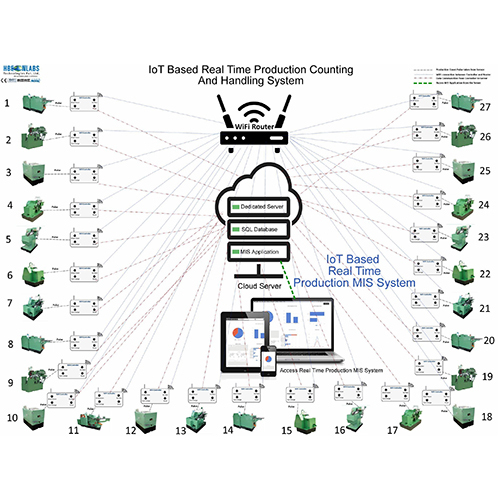

About IoT-based Production Output Monitoring System

Jump on the industrial automation trend with our IoT-based Production Output Monitoring System, a prime, top-notch solution for real-time production line monitoring. This highly recommended, sought-after device boasts up to 8 digital inputs, fast <1-second response times, and an impressive 1,000,000 counting capacity. Ensure security with AES 256-bit encryption, while OTA firmware updates, role-based user management, integrated maintenance logging, and a robust 2-hour UPS make this solution reliable and future-ready. Satisfying diverse requirements, it supports modular expansion, direct cloud/server data transmission, and seamless compatibility with Ethernet, WiFi, MQTT, and Modbus-perfect for modern factories.

Versatile Application, Advanced Features, Industrial Plant Integration

The IoT-based Production Output Monitoring System is engineered for seamless installation on industrial production lines. Application is straightforward-simply wall or panel-mount the IP65-rated enclosure, attach compatible sensors, and connect using Ethernet, WiFi, or Modbus. Special features like real-time monitoring, multi-user role-based management, and integrated maintenance logs with notifications deliver superior oversight. This system is an excellent fit for high-demand plant environments, offering robust, customizable monitoring tailored to each production unit's needs.

FOB Port, Premium Certifications, and Fast Dispatching

Each IoT-based Production Output Monitoring System is carefully packaged to ensure product integrity during transit. Orders are dispatched from premium FOB ports across India with prompt delivery schedules-standard delivery time typically ranges from 2 to 4 weeks depending on customization and location. This product comes with all relevant industrial certifications, reflecting top-notch quality and meeting industry compliance standards. Trust us for safe, timely delivery and an exceptional purchase experience every time you place an order.

FAQ's of IoT-based Production Output Monitoring System:

Q: How does the IoT-based Production Output Monitoring System enhance production line oversight?

A: The system provides real-time, cloud-connected monitoring and analytics, enabling quick detection of anomalies, performance bottlenecks, and maintenance needs. Multi-user, role-based access ensures that relevant data is accessible to authorized personnel for faster decision-making.

Q: What are the key benefits of integrating this solution into my plant?

A: You gain expandable, secure, and highly accurate monitoring with real-time alerts, automated maintenance logs, and simplified data management. The device's compatibility with various communication protocols eases integration into existing systems, boosting efficiency and minimizing downtime.

Q: Where can this monitoring system be installed within a manufacturing plant?

A: The rugged, industrial-grade, IP65-rated enclosure supports wall or panel mounting, making it suitable for harsh industrial environments, on production floors, in equipment rooms, or main control centers.

Q: When should firmware upgrades be performed, and is there any downtime involved?

A: Firmware can be upgraded over-the-air (OTA) at any convenient time. The upgrade process is designed to be seamless with minimal service interruption, ensuring ongoing productivity.

Q: What is the process for exporting collected production data?

A: Data can be exported easily in CSV or JSON formats from the system's web dashboard or mobile apps, facilitating in-depth reporting and integration with third-party enterprise software.